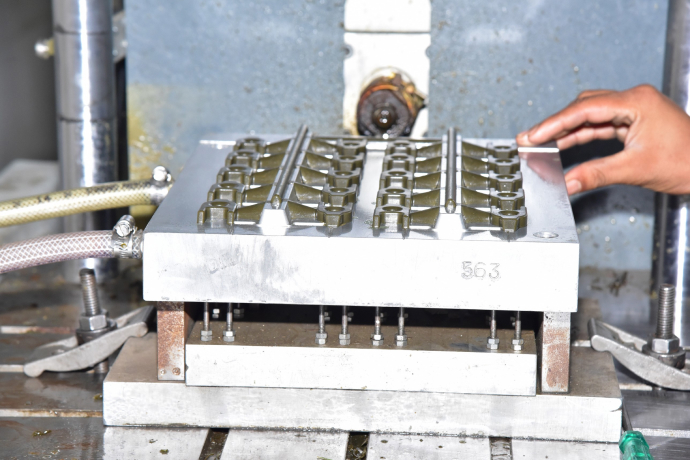

WAX INJECTION

- The Investment Casting process starts with wax injection.

- Automatic and semi-automatic indigenous wax injection presses play a crucial role in achieving the desired wax pattern with consistent control over dimensions and surface requirements.

- Ability to produce wax patterns with soluble and urea cores for critical requirements.

- The cleaning, repairing, inspection, and assembly areas, respectively.

- Finished patterns move forward to the cleaning, repairing, inspection, and assembly areas, respectively.

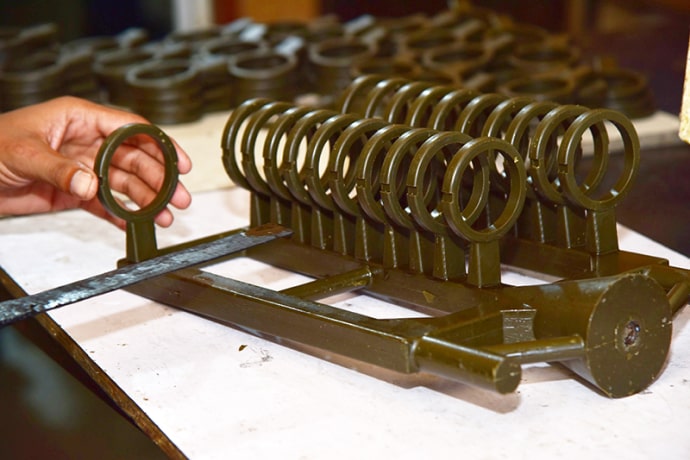

WAX ASSEMBLY

- Highly experienced professionals are responsible for finalizing the assembly design to achieve desired results.

- The finished pattern is assembled with gates, runners, risers, and a pouring cups.

- The finished wax assembled tree moves forward to the primary coating area.

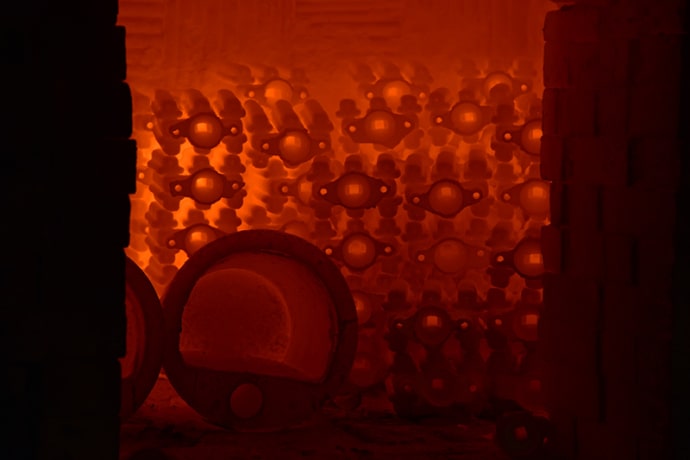

SHELL MAKING

- The finished wax assembled tree is dipped in viscous ceramic slurry, and zircon sand coating is applied.

- The shell is moved to an air-conditioned drying area with controlled temperature and humidity to achieve the desired permeability and surface finish.

- This process is repeated 7 to 10 times, depending on the complexity of the parts.

- The finished shell then moves forward to the de-waxing area.

DE-WAXING

- An autoclave boiler is used to melt and extract the wax from the shell.

- The wax melts out of the shell and is collected in a separate tank.

- The hollow shells move forward to shell storage and the pouring waiting area.

SHELL BACKING

- Shell backing is carried out in a gas-fired furnace for pre-heating before pouring.

- The temperature of the shell is controlled through a temperature controller.

- Pre-heated shells are then moved forward to the pouring bed.

MELTING

- Furnaces with 150 kg and 350 kg crucibles are used for melting the desired metal.

- Pouring is carried out onto pre-heated shells to complete the casting process. The shells remain on the pouring bed until they cool naturally.

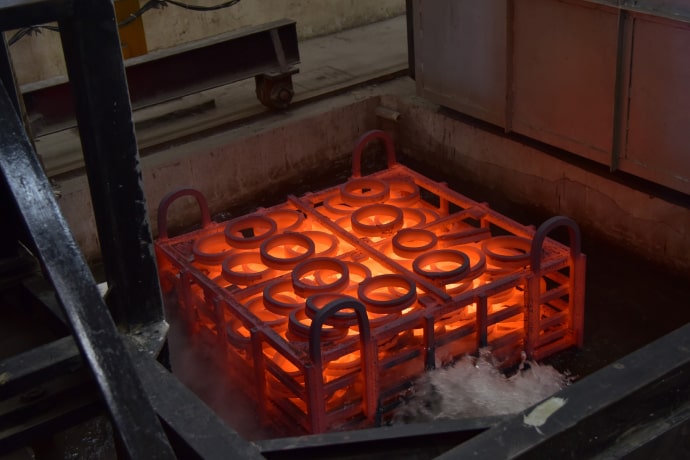

HEAT TREATMENT

- After gate cutting, the shell material moves on to the heat treatment process, which involves heating or chilling the material to achieve the desired mechanical properties.

KNOCKOUT, FETTLING & SHOT BLASTING

- Knockout process carried out to remove shell from casting.

- To remove the ceramic materials from the casting, the cutting and fettling processes are carried out after the knockout process to remove gate burrs and other residual materials from the casting.

- The sand/shot blasting process is carried out on fettled parts to achieve the desired surface finish.

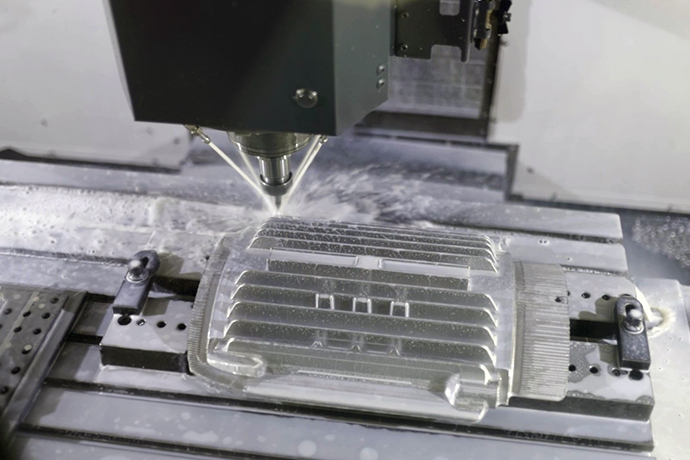

MACHINING

- To cut or remove material from a casting part in order to achieve more accurate dimensions.

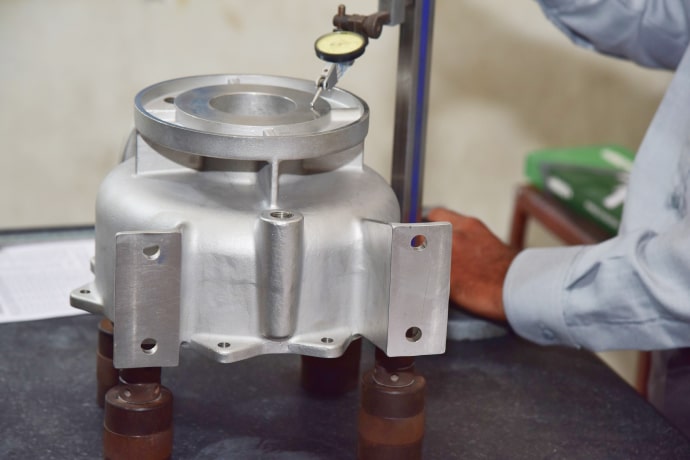

INSPECTION

- Machined and as-cast components are inspected by qualified quality control personnel or inspection technicians who are trained in specific areas.

PACKING & DISPATCH

- After final inspection, the material will be packed and sent to customers’ locations around the globe.